Materials innovator 3form proudly announces the launch of Know New Plastic—an initiative combining mechanical recycling with revolutionary new molecular recycling methods to increase the amount of recycled content in the company’s materials. The initiative begins with their Textures Collection, which is now made from 100% recycled content. The company's focus on leveraging cutting-edge molecular recycling technology underscores its commitment to environmental stewardship, expertise in translucent material, and unique capabilities to create a material entirely from waste that doesn’t lose aesthetic value or quality.

Molecularly recycled resin has a lower carbon footprint than conventionally produced resin, transforming waste like synthetic fibers in clothing, carpet fibers, dense plastic containers, and packaging into durable materials. Molecular recycling uses plastics unsuitable for mechanical recycling and breaks them down into their molecular components. These molecules can then form new high-quality materials. This process allows for the recycling of a wider variety of existing plastics and can help lower the production of more plastics from newly extracted fossil fuels. “Using this technology we can provide a new home for plastics that would otherwise be destined for landfill, said Lauren Smith, Sustainability Director at 3form. “By using this content we’re avoiding the need to use and extract raw materials from the earth.”

Key highlights of 3form’s molecular recycling initiative include:

Waste Diversion: By diverting plastic from landfills, 3form actively contributes to environmental conservation efforts. One textured Varia panel (100% recycled) diverts the equivalent of 3,296 plastic water bottles from the landfill—stacked on end, that's 7.2 times the height of the Statue of Liberty.

Reduced Carbon Emissions: By using molecularly recycled material in their Varia panels, 3form can reduce manufacturing emissions by 25% compared to using virgin material.

For every 50,000 LBS of molecularly recycled material processed, 21,000 LBS or 10 Metric Tons of CO2 equivalent emissions are avoided. That's equivalent to the emissions from 23,636 miles driven in the average passenger vehicle or almost one trip around the earth (95% of the way).

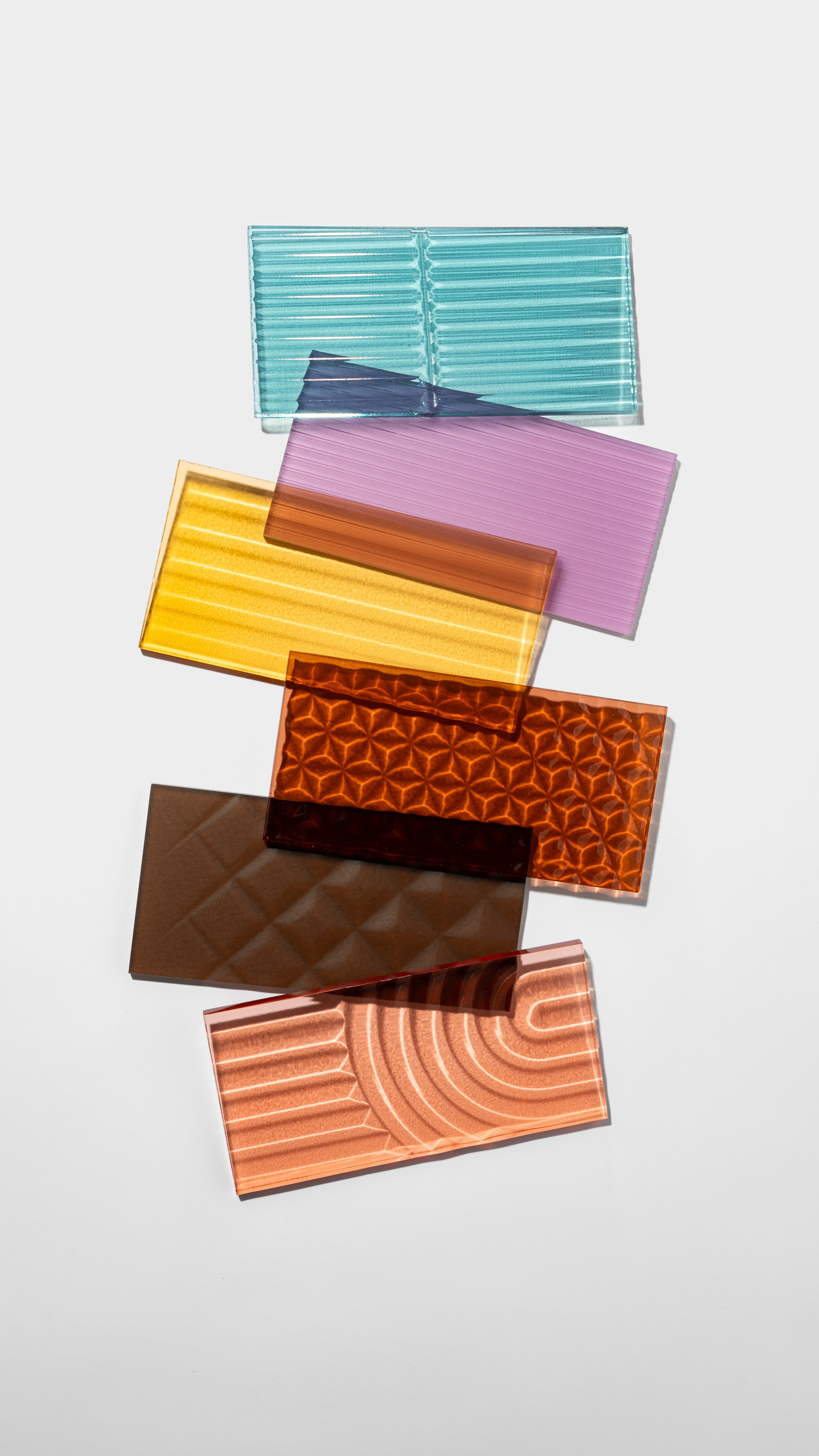

3form is introducing the new technology with the launch of 100% recycled Textures. The company offers 21 texture options all made from 100% recycled material without compromising the translucency and durability expected from 3form.

“The Textures Collection’s shift to 100% recycled materials comes at no cost to our customers—that’s how committed we are to producing sustainable products,” said Karli Slocum, Vice President of Product & Marketing. “We want to create an incentive to buy non-virgin material, and we don’t want to pass the cost along to our customer, making our products harder to specify.”

Looking ahead, 3form plans to extend the initiative beyond the textures line, integrating recycled content across their entire Varia line. The company envisions a future where plastic waste is repurposed into high-quality architectural materials, driving a shift towards a circular economy for the company and the industry. 3form aims to eventually eliminate virgin material usage in their Varia line entirely.

"Sustainability is ingrained in our organization's DNA. We have a 20-year history of investments that have honed our expertise. This commitment has enabled us to harness our extensive knowledge allowing us to quickly embrace technologies like molecular recycling,” said Slocum. “Integrating these new recycling technologies allows us to innovate and lead our industry in making impactful changes. It's inspiring to create beautiful architectural grade resin while diverting waste from landfills."

As part of its commitment to transparency, 3form is pursuing certification from a third party which is expected in late spring.